Post-tensioning is a method of applying compression after pouring concrete. Galvanised duct which is profiled using bar chairs follows the area where otherwise tension would occur in the concrete element. Steel strand (12.7mm typically) is pushed through the duct (known as tendons) and the concrete is poured. Once the concrete has achieved required strength, the tendons are stressed by hydraulic jacks. When the tendons have extended to the design specifications, they are wedged in position to maintain tension after the jacks are removed. The duct is then grouted to provide corrosion protection and to bond the strand to the concrete members.

Post-tensioned slabs have many advantages over reinforced concrete slabs and other structural systems for both single and multi-level structures.

Some benefits include:

- Longer Spans

- Overall Structural Cost

- Reduced Floor to Floor Height

- Deflection Free Slabs

- Waterproof Slabs

- Early Formwork Stripping

- Reduced Materials Handling

- Economical Column and Footing Design

1. Longer Spans

Longer spans can be used reducing the number of columns. This results in larger, column free floor areas which greatly increase the flexibility of use for the structure and can result in higher rental returns.

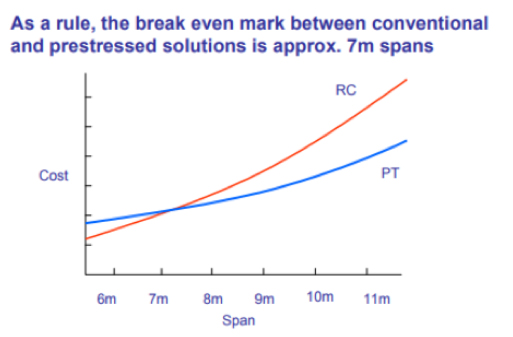

2. Overall Structural Cost

The total cost of materials, labour and formwork required to construct a floor is reduced for spans greater than 7 metres, thereby providing superior economy.

3. Reduced Floor to Floor Height

For the same imposed load, thinner slabs can be used. The reduced section depths allow minimum building height with resultant savings in facade costs. Alternatively, for taller buildings it can allow more floors to be constructed within the original building envelope.

4. Deflection Free Slabs

Undesirable deflections under service loads can be virtually eliminated.

5. Waterproof Slabs

Post-tensioned slabs can be designed to be crack free and therefore waterproof slabs are possible. Achievement of this objective depends upon careful design, detailing and construction. The choice of concrete mix and curing methods along with quality workmanship also play a key role.

6. Early Formwork Stripping

The earlier stripping of formwork and reduced back propping requirements enable faster construction cycles and quick re-use of formwork. This increase in speed of construction is explained further in the next section on economics.

7. Materials Handling

The reduced material quantities in concrete and reinforcement greatly benefit on-site cranage requirements. The strength of post-tensioning strand is approximately 4 times that of conventional reinforcement. Therefore the total weight of reinforcing material is greatly reduced.

8. Column and Footing Design

The reduced floor dead loads may be utilised in more economical design of the reinforced concrete columns and footings. In multi-storey buildings, reduced column sizes may increase the floor net lettable area.

Cross, Ed. Article – Post Tensioning in Building Structures, Retrieved from http://www.ptia.org.au

Brochure download

Tensioned Concrete Brochure (PDF 5MB)